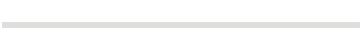

Laboratory of simulation of flow processes

The physical model of tundish U. S. Steel Košice, s.r.o. |

||

|

||

The physical model of tundish ŽP a.s. |

||

|

||

The physical model of tundish U. S. Steel Košice, s.r.o. |

||

|

||

The physical model of tundish ŽP a.s. |

||

|

||

Professional publications

BUĽKO, Branislav - MOLNÁR, Marek - DEMETER, Peter - BARICOVÁ, Dana - PRIBULOVÁ, Alena - FUTÁŠ, Peter, Study of the influence of intermix conditions on steel cleanliness, In: Metals. - Basel (Švajčiarsko): MDPI Roč. 8, č. 10 (2018), p. 1-9 [online]. - ISSN 2075-4701 (online)https://www.mdpi.com/2075-4701/8/10/852/htm...

BUĽKO, Branislav - PRIESOL, Ivan - DEMETER, Peter - GAŠPAROVIČ, Peter - BARICOVÁ, Dana - HRUBOVČÁKOVÁ, Martina, Geometric Modification of the Tundish Impact Point, In: Metals. - Basel (Švajčiarsko): MDPI Roč. 8, č. 11 (2018), p. 1-11 [online]. - ISSN 2075-4701 (online)https://www.mdpi.com/2075-4701/8/11/944/htm...

|

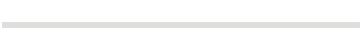

The aim:

|

||||

.jpg)

|

|

|

||

The laboratory provides:

|

||||

Mesh generation |

|

|

|

Postprocessing |

|

|

|